YUEHELE

Guangdong Yuehele Label Material Co., Ltd. is a high-tech enterprise integrat

ing scientific research, production, sales, technical support and service for users.

PVC stickers are durable, flexible labels made from polyvinyl chloride (PVC), a synthetic plastic polymer. Unlike paper or standard vinyl stickers, PVC offers unique properties that make it ideal for demanding environments. Below is a detailed breakdown of their features and applications

Core Characteristics of PVC Stickers

| Property | Description |

|---|---|

| Material | Plasticized PVC (flexible) or rigid PVC |

| Thickness | 0.1–2.0 mm (adjustable for rigidity/flexibility) |

| Durability | Waterproof, UV-resistant, chemical/oil-proof, abrasion-resistant |

| Flexibility | Conforms to curved surfaces (e.g., bottles, tools) |

| Temperature Range | -20°C to 80°C (short-term tolerance up to 100°C) |

| Finish Options | Glossy, matte, textured, metallic, or clear |

| Lifespan | 5–10+ years outdoors (vs. 1–3 years for standard vinyl) |

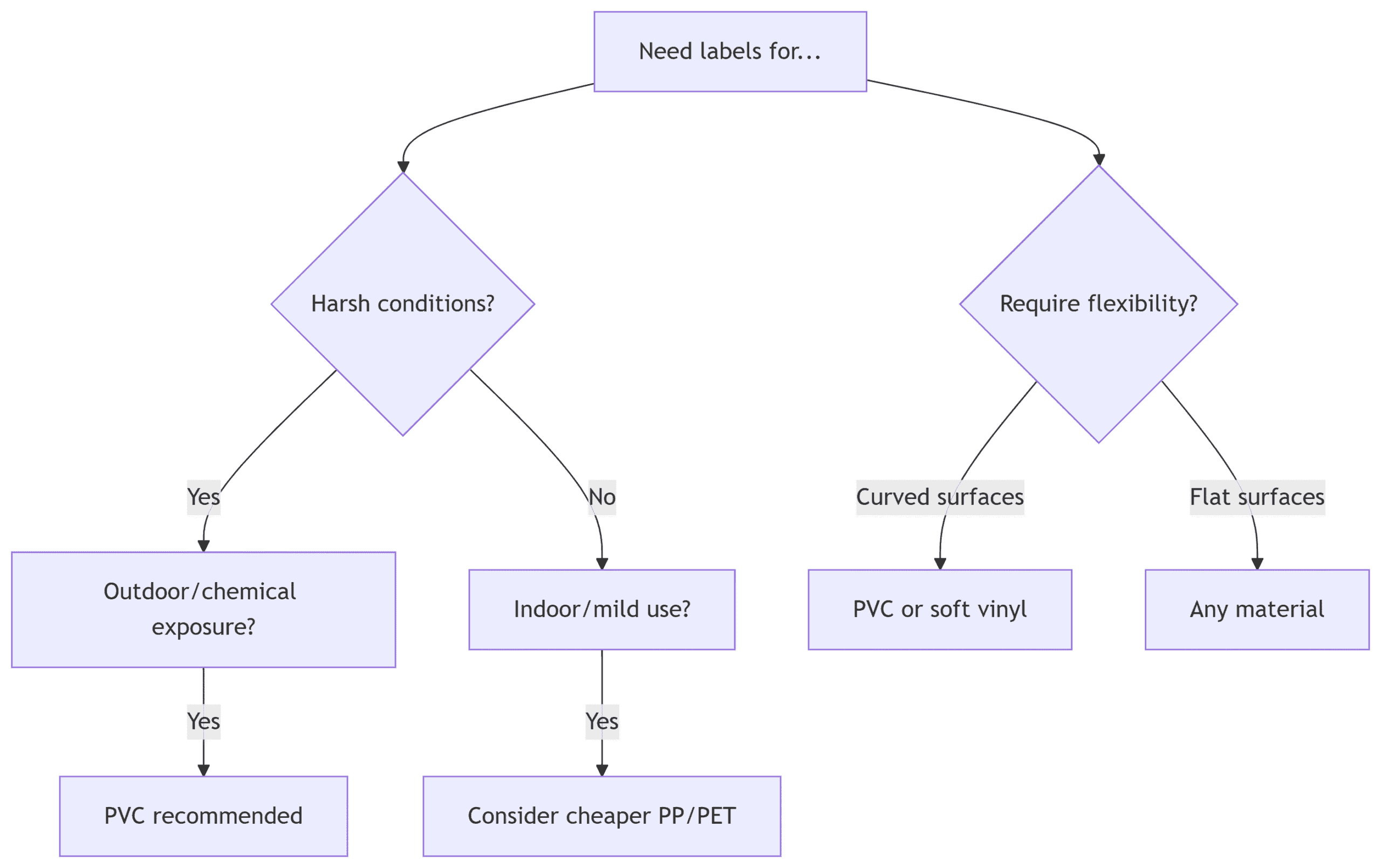

When to Choose PVC Stickers

Key Applications

1. Industrial & Automotive

- Machine safety labels: Warning tags on equipment.

- Automotive badges: Brand emblems on cars/motorcycles.

- Tool identification: Labels for drills, generators.

- Chemical drum marking: Resistant to solvents/oils.

2. Outdoor & Harsh Environments

- Marine labels: Boat registration decals (saltwater-resistant).

- Agricultural tags: Tractor/implement labels (mud/dust-proof).

- Pool equipment: Chlorine exposure resistance.

3. Branding & Retail

- Premium product labels: Wine/spirit bottles, cosmetics.

- Promotional decals: Event giveaways (indoor/outdoor).

- Retail shelf tags: Reusable pricing labels.

4. Specialized Uses

- Medical devices: Biocompatible grades for FDA-compliant labels.

- Electronics: Insulating labels on wiring/power tools.

- Tamper-evident seals: Destructible PVC for security.

PVC vs. Common Label Materials

| Feature | PVC | Vinyl | PP/PET Films |

|---|---|---|---|

| Water Resistance | ★★★★★ | ★★★★☆ | ★★★☆☆ |

| Chemical Resistance | ★★★★★ | ★★★☆☆ | ★★★★☆ |

| Tear Strength | ★★★★☆ | ★★★☆☆ | ★★★★★ |

| Flexibility | ★★★★★ | ★★★★☆ | ★★★☆☆ |

| Cost | High | Medium | Low-Medium |

Production Methods

- Digital Printing

- Short runs, full-color designs.

- Requires UV-resistant inks for outdoor use.

- Screen Printing

- Thick ink layers (ideal for metallic/glow-in-dark effects).

- Die-Cutting

- Precision shapes (e.g., logos with intricate outlines).

Limitations & Considerations

⚠️ Environmental Impact:

- Traditional PVC contains phthalates (avoid with eco-certified phthalate-free PVC).

- Recycling challenges (seek recyclable PVC variants).

⚠️ Adhesive Compatibility:

- Use solvent-based acrylic adhesives for long-term bonding.

- Avoid rubber-based adhesives (plasticizer migration causes failure).

⚠️ Regulations:

- EU/UK: Comply with REACH, RoHS for restricted substances.

- Food Contact: Requires FDA 21 CFR or EU 10/2011 compliance.

leave a message

leave a message