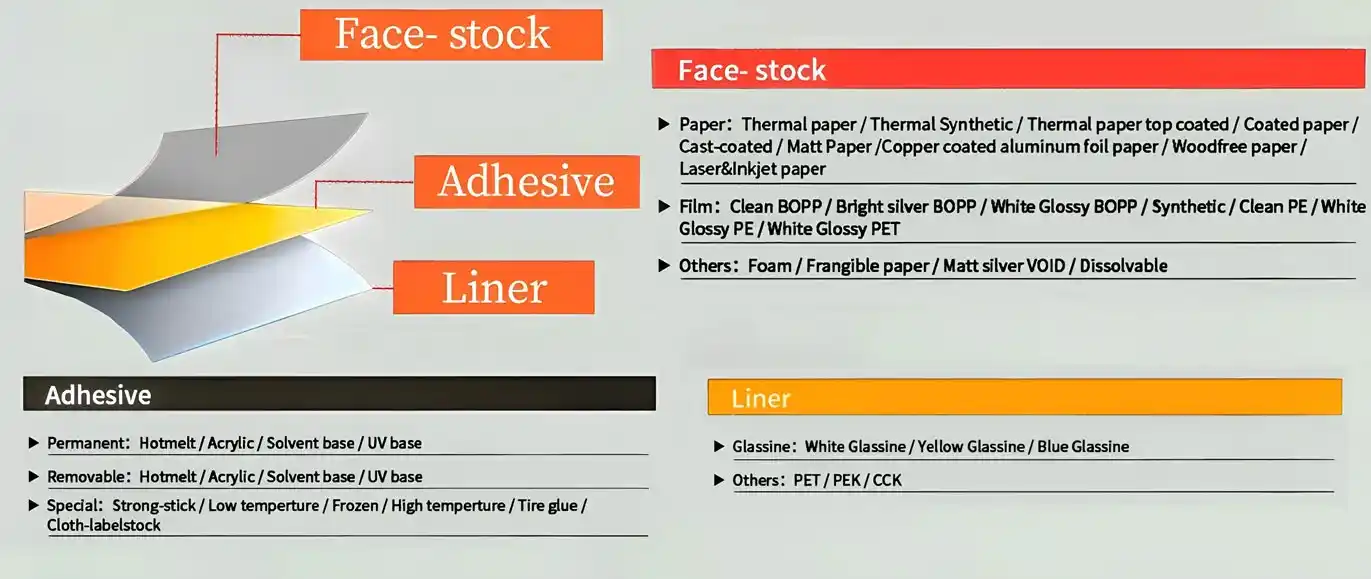

Product introduction: PEK coated release paper, kraft paper with PE film, is competitively priced. It combines the characteristics of GLS and CCK. It is flat and not easy to deform, has good toughness, is resistant to punching and shearing, and can withstand high mechanical pressure. It is Ideal industrial paper, suitable for advertising materials, stickers, electronic die-cutting, etc.;

Features:

1.PE-coated release backing paper. Uses: various advertising materials, self-adhesives, electronic die-cutting, etc. Instructions for use: 1. Storage requirements: Storage temperature is 22-28°C, relative humidity is 50%-70%. It is best to avoid direct sunlight and high temperature (above 40℃) and high temperature (above 70%RH) conditions.

2. The product may become static during rewinding, slitting or use. It is recommended that users install static elimination equipment on the machine.

What Are the Performance Standards for Release Liners in Label and Graphic Applications?

Release liners are critical components in the label and graphic industries. They ensure smooth application and optimal performance. Here’s what you need to know about the key performance standards:

- Coating Precision: Release liners must have a uniform coating to facilitate easy peeling and application. Any inconsistency can lead to errors during the label application process.

- Die Cutting Compatibility: For efficient and precise die-cutting, the liners need to withstand the cutting process without tearing or affecting the adhesive layer of the label.

- Application Reliability: The liner should enable easy removal without leaving any residue, ensuring the label adheres smoothly to various surfaces. This is crucial for maintaining the aesthetic and functional integrity of the labels.

- Durability: They must resist environmental factors such as temperature fluctuations and moisture, which could otherwise compromise the application process or alter the functionality of the liners.

- Silicone Release Characteristics: The silicone layer must offer consistent release force, allowing for easy and repeatable removal. Varying release forces can cause application issues and inefficiencies.

By meeting these stringent standards, release liners ensure that both labels and graphics adhere perfectly, enhancing their effectiveness and quality.

3. This information is a product description. All information and data are obtained after testing. We believe that it can be provided to users for reference only. It does not represent the actual value of each product. Each product cannot be adapted to the usage of all products. In actual practice,Before applying this product, it is recommended to test it first.