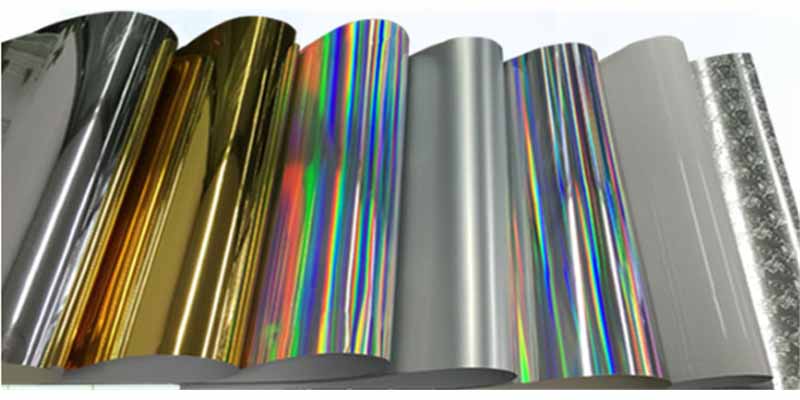

Many businesses often inquire about the materials used in holographic anti-counterfeiting labels. According to anti-counterfeiting technology experts, the choice of label material depends on the specific type of holographic label required. Several materials are widely used in the industry, each with its own unique properties and applications.

Common Materials:

- Paper-based adhesives: These are cost-effective and suitable for many basic applications.

- PVC (Polyvinyl Chloride): Offers durability and versatility, making it popular for various products.

- PET (Polyethylene Terephthalate): Known for its strength and resistance to environmental factors.

Specialized Materials:

- Aluminum oxide laser film: Used specifically for laser labels, providing high-quality holographic effects.

- Fiber paper: Employed in texture-based anti-counterfeiting, offering a unique tactile experience.

- Fragile paper: Utilized in tamper-evident labels that easily break upon attempted removal.

- Special windowed anti-counterfeiting paper: Used in certain specialized labels, allowing for partial transparency.

The choice of material is crucial in determining the effectiveness and durability of the anti-counterfeiting label. Factors such as the product type, environmental conditions, and desired security features all play a role in material selection.

Holographic anti-counterfeiting labels serve as a vital tool in protecting brand integrity and consumer trust. By utilizing advanced materials and technologies, manufacturers can create sophisticated security features that are difficult to replicate, thus safeguarding their products from counterfeiters.