YUEHELE

Guangdong Yuehele Label Material Co., Ltd. is a high-tech enterprise integrat

ing scientific research, production, sales, technical support and service for users.

“Deplasticization” typically refers to separating plastic components from composite materials to enable recycling. For paper-based adhesive labels, the key factor is whether the face material (the printable paper layer) contains plastic:

Pure Paper Face Material (No Plastic Coating):

- These labels use standard paper (e.g., coated paper, writing paper) without a plastic film laminate.

- They do not require specialized “deplasticization”.

- When discarded, they could theoretically be recycled as ordinary waste paper. However, there’s a major caveat:

- Adhesive and Liner are Contaminants: The adhesive backing and the removed liner paper (typically silicone-coated glassine or kraft paper) pollute paper recycling streams. Large amounts of adhesive, silicone, and other residues degrade recycled pulp quality and can damage machinery.

- Disposal Advice: For recyclable items (e.g., glass/plastic bottles) with such labels, remove labels and adhesive residue before recycling the container. Discard labels/liners as residual waste (dry waste) to avoid contaminating recyclables. Isolated unused pure-paper labels may be placed in paper recycling in small quantities, but large volumes should be confirmed with local recyclers. Safer option: treat as residual waste.

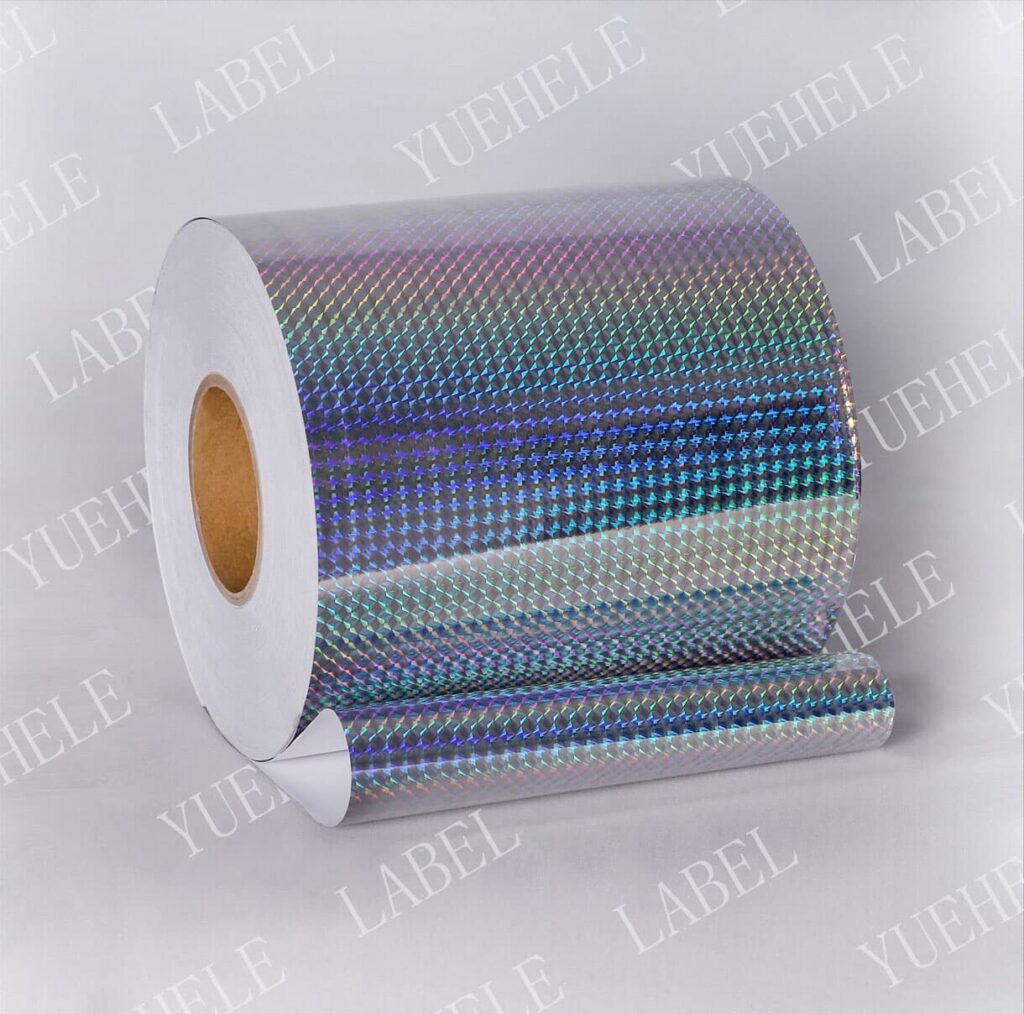

Plastic-Coated Paper Face Material:

- This is very common. To enhance water/oil resistance, durability, or print quality, many paper labels have a thin plastic coating (usually polyethylene PE or polypropylene PP). Examples include:

- Thermal labels (e.g., supermarket receipts, shipping labels): Often have a PE coating to protect the heat-sensitive layer.

- Waterproof/oil-resistant labels (e.g., for cosmetics, food packaging).

- Matte/gloss coated paper labels: The surface finish is typically a plastic film.

- These labels are paper-plastic composites.

- They require “deplasticization” to recycle the paper component. In standard paper recycling:

- The plastic coating is a contaminant: During pulping, the plastic film doesn’t dissolve but fragments into impurities, causing defects (spots, holes) and reducing pulp strength.

- Conventional facilities cannot process it: Most paper mills lack technology to separate thin plastic coatings from paper.

- Recycling Reality:

- Not accepted in mainstream recycling: Plastic-coated paper labels (like other composites e.g., beverage cartons, paper cups) cannot enter standard paper/plastic recycling streams. They are typically treated as residual waste, ending up in landfills or incinerators.

- “Deplasticization” tech exists but is scarce: Specialized processes (e.g., hydrapulping with thermal dispersion, solvent treatment) can separate fibers and plastic, but these are costly and complex. They are rarely used for low-value post-consumer waste like labels.

- Disposal Advice: Discard plastic-coated paper labels as residual waste (“其他垃圾”/dry waste). Do not place in paper recycling bins.

How to identify plastic coating on paper labels:

- Visual/Tactile Check: Glossy, waterproof, or “plastic-like” surfaces likely have coating.

- Tear Test: Peel an edge; visible delamination (paper layer + thin transparent film) indicates coating.

- Water Test: Place a water droplet on the surface. Beading (water repelling) suggests plastic coating; absorption indicates uncoated/treated paper (not foolproof).

NEWS

- New material solutions

- What are the common specifications of thermal paper?

- Paper categories and properties

- which foods are not required to have a nutrition label-US

- Can you use regular paper in a thermal printer-China

Summary:

- Pure paper (uncoated) labels: No “deplasticization” needed, but adhesive/liner makes them unfit for paper recycling. Remove and discard as residual waste to avoid contaminating recyclables.

- Plastic-coated paper labels: Require “deplasticization”, but current systems cannot effectively process them. They are composite waste—discard as residual waste.

leave a message

leave a message